How 3D printers work and how to use them

What is 3-D printing? 3D printing takes a 3D laptop version and turns it into a actual object. It does this by means of adding material collectively, commonly a layer at a time, hence permitting almost any shape to be created with relative ease.

How 3D Printers Work

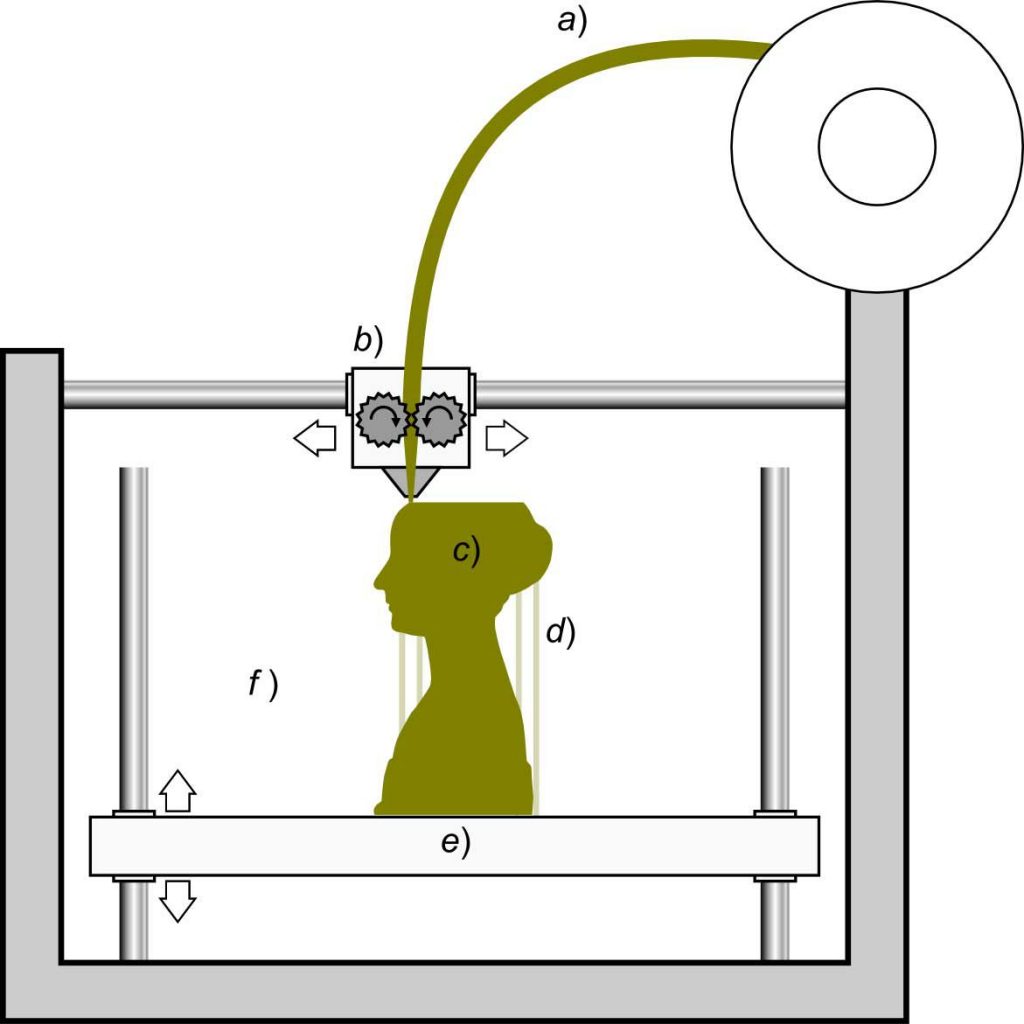

Most domestic 3D printers use Fused Deposition Modelling (FDM). This makes use of a filament of plastic fabric, a bit like a string. The filament is fed from a roll right into a heated head, which melts the plastic.

To start generating a component, the pinnacle extrudes melted plastic onto the mattress of the machine. The head moves over the mattress, in 2D, depositing the first layer of fabric.

Once the primary layer is entire, the pinnacle is moved up, by the thickness of the primary layer, and starts offevolved depositing the subsequent layer on top of it. The component is built up layer-by using-layer.

Popular FDM three-D printers consist of MakerBot and Ultimaker. You may even construct your personal printer through following the instructions at the open supply challenge RepRap.

What is 3-D printing, How to Use a 3D Printer

01. Download a 3D version you need to print, or layout one yourself. You can find one to download on Thingiverse or GrabCAD. To design a version, you may use Google SketchUp or Blender. For engineering elements, Computer Aided Design (CAD) software program, along with SolidWorks, is better.

02. If it isn’t already, convert your model into a 3-D printing format, together with an .STL report or .OBJ.

03. Import your model into slicing software program, which include MakerWare, Cura or Simplify 3-d. MakerWare works with MakerBot 3-D Printers. Cura and Simplify three-D produce G-code which matches with maximum 3-d printers.

04. Configure the build for your cutting software program. First, you need to determine a way to orientate your model on the 3-d Printer. For FDM, you need to minimize overhangs steeper than 45 tiers, due to the fact that these will require assist systems.

When deciding on the orientation you may also need to bear in mind how the model may be loaded so layers may not be without problems separated, that is a piece like the use of the grain in timber. You may control how aid structures are introduced to the version.

What is 3-D printing, 3D Printer

To shop time and substances, models are usually now not strong. You specify the infill percentage (commonly 10-35 percentage), the variety of perimeter layers (normally 1-2), and the variety of bottom and top layers (usually 2-four). There are masses of different matters to don’t forget when preparing your model for 3-D printing.

05. Export this system, generally a G-code record. Your cutting software program will convert your model, and the build configuration you certain, into a hard and fast of commands. Your three-D printer will comply with this to construct the element.

06. Transfer the program in your 3D printer the use of an SD card, USB, or Wi-Fi.

07. Print the version to your 3-d printer.

08. When the 3-D printer has finished building your model, you’ll need to do away with it and likely additionally smooth it. You should spoil off any guide systems and rub off any final lumps with a great sand paper.

Other Types of 3-D Printing Machines

In the beyond, 3-d printing become referred to as fast prototyping, on the grounds that that is what it changed into used for. In current industry, 3D printers at the moment are capable of produce brilliant components and the term additive production is commonly used. Three-D printing is normally used to refer to each business additive manufacturing and 3-D printers designed for domestic model making.

Industrial additive production commonly makes use of a few shape of 3-D laser printer. These regularly have tanks full of powdered or liquid material. A laser then lines out a profile at the pinnacle floor of the cloth, forming it right into a strong layer. Ultraviolet lasers are used to cure liquid resin into stable plastic. High-powered lasers are used to warmness powdered plastic, metallic, or ceramic, until it fuses collectively.

What is 3-D printing, The Future of 3D Printing

You’ve probably study somewhere your home 3-d printer will quickly make everything you want. You’ll clearly down load a record and it’s going to print your clothes, spare components for your car, and possibly even your dinner. Take those claims with a pinch of salt.

One wonderful statement claimed 3D printers in China built 10 homes in an afternoon, at a cost of just $five,000 according to house. In truth, each 3-D revealed house changed into only a unmarried room and they handiest simply made the partitions and the roof, which make up much less than 10 percent of the cost of a residence. Land aside, most of the build cost isn’t for the basic shape. Other such things as plumbing, electrics, insulation, and carpentry upload up to value loads more. So don’t count on to buy your subsequent house for $5,000.

In maximum instances, 3-d revealed components are either much lower first-rate or a whole lot extra costly than elements produced using more traditional strategies. In many cases, they’re each. 3-D printing isn’t everywhere near replacing traditional manufacturing.

So what is 3D Printing Good For?

3D printing has been used for many years for brief low-electricity prototypes. This sort of 3-D printing is now affordable and best for home model makers. It also can be beneficial for changing matters around the house which are tough to locate, consisting of matching knobs and handles on cookers or furnishings. If the element doesn’t want to be specially robust, 3-D printing may be a terrific alternative.

In enterprise, three-D printers are used to supply complicated aerospace components, optimized for energy and weight. If numerous very special machining or casting would be required, 3D printing can be reasonably-priced. There also are plenty of emerging packages in medication for three-D printing producing tissue scaffolds for body components.