3D Printer Settings, Having hassle with your 3-d printer settings? Follow this step-by way of-step guide for tips and hints.

01 Adjusting 3D Printer Settings:A Little Heat and Speed Change

Helpful hint: An smooth cheat in case you don’t need to try to regulate matters by using hand is to utilize dual print heads.

The usage of one extruder for the model and one for a raft, ensuring to enable purge walls.

This reasons the print head to transport away from the version, accordingly letting the version layer cool, retracts filament, wipes it at the purge wall.

Repeats for the second one extruder, accordingly robotically creating a cooling of the version layers and velocity discount at the model print area.

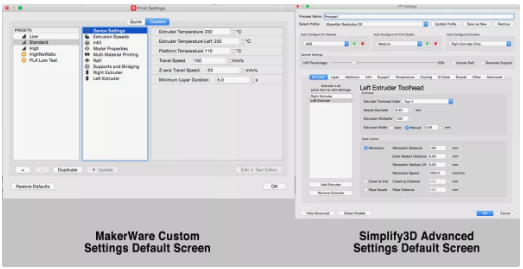

02 3D Printer Settings, Using 2 Different FFF Settings

As an example, the Police Call Box is going to be configured with a 90% infill and four perimeter outlines.

At the same time as the top (which includes the spire) segment may have a 10% infill with 2 shells.

This will create a heavier base and keep it from tipping over without difficulty.

Two (2) distinct FFF settings can be created in Simplify3D, one for every location.

First, determine in which the transition from ninety% to 10% should take area; just beneath the pinnacle stage of windows.

The preview approach mentioned earlier may be used or in Simplify3D.

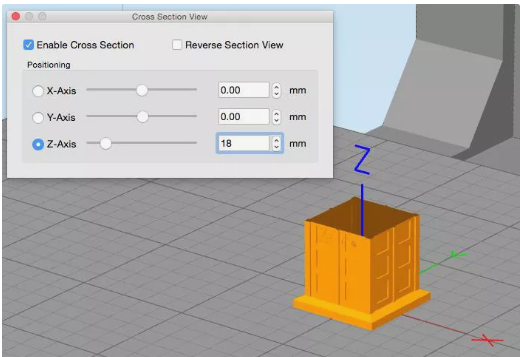

The version may be sliced using the Cross Section Tool permitting the consumer to look in the model.

[View > Cross Section] Move the slider up and down the Z-aircraft axis until.

The model is slice simply under the top window, so 18mm. Write this wide variety down.

03 3D Printer Settings, Simplify3D Settings for Different Areas

First, determine where the transition from 90% to 10% ought to take location; simply under the pinnacle stage of windows.

The preview method referred to in advance may be used or in Simplify3D.

The model can be sliced using the Cross Section Tool permitting the consumer to look within the model.

[View > Cross Section] Move the slider up and down the Z-aircraft axis till the version is slice just under the top window, so 18mm.

Write this number down.

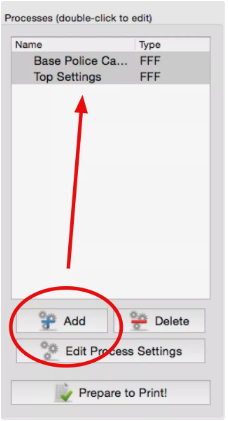

04 3D Printer Settings, Adding a New Region to Allow for Different Extrusion Setting

Then upload a brand new FFF Process for the first vicinity, the bottom, settings.

Once they’re configured a second process could be created of the second region, the pinnacle, settings.

05 3D Printer Settings, Changing Perimeter Settings for Your 3D Model

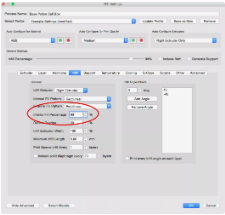

Once the primary technique has been created for the bottom.

Navigate to the Layer tab and trade the Outer Perimeter Shells from 2 to four.

06 Infill Settings Can Differ From Perimeter Settings

Next is to trade the infill to ninety% at the Infill tab.

07 Changing Settings for Different Areas of Print Job

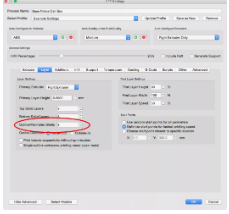

Next designate what layers to use this process in the Advanced tab.

For the base, it will likely be from the bottom to the 18mm stage decided previously.

The settings for the base have now been set; click OK to save the settings for this manner.

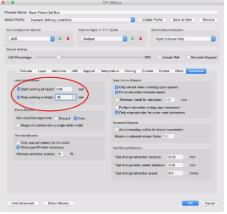

Create the second one system for the top portion via traveling the same tabs and converting the shells on the Layer tab to 2.

The Infill to ten%, and the place to print from 18mm to the top on the Advanced tab.

Be certain to click on OK to store the settings for the second technique.

08 Time to Print: Advanced Slicing Settings

3D Printer Settings, Once each manner have been created it’s time to print the model.

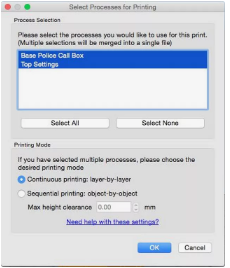

Click Prepare to Print and while the Select Process for Printing window seems pick out select all to apply both configurations.

It is continually a good concept to run the preview print to see.

How the model goes to look earlier than clearly committing the print time and materials.

The above display screen capture video shows the how the Police Call Box may be published covered the difference inside the regions.

There are many, many other features that can be modified for an person print.

And it is a lot of questioning and head scratching, trial and blunders, and failed prints till the best print is made.

But with perseverance, planning, appropriate design, mesh restore, and custom print configurations.

FDM/FFF printers are able to printing plenty of cool stuff!

Thanks to Sherri Johnson and Yolanda Hayes at Catzpaw Innovations for this special slicing and 3-d printing academic.